Current status of the inverter installation for the crane - Gate crane

Currently, many companies operating in the concrete field use a lot of crane systems and gate axes to move heavy structures such as molds, bored piles, electric poles, concrete slabs ... but solutions to install inverters. for the control system is hardly concerned.

Gate crane Crane shaft

The crane girder system control consists of 2 main parts: the lifting control and moving control of the crane girder.

The crane girder movement is done by 2 motors pulling the steering wheel system under the girder's foot. Capacity of 2 motors depends on the weight of the girder. These two motors use common power source and run / stop at the same time through the system of buttons on the remote control.

Disadvantage / Harm if not install inverter for crane, gate shaft

When 2 motors are powered directly from the 3-phase / 380VAC grid and at the same time, this leads to:

- The crane girder will be twisted, causing danger to the operator.

- Reducing the life of the mechanical part of the girder.

- Electrical energy is dissipated because the starting current is higher than the rated working current.

- Causing a drop in network voltage when starting up, affecting the quality of the electrical network of the whole system.

- The crane girder will vibrate when the motor stops and starts, which shortens the life of the gear system and bearing.

- High cost of girder maintenance

Benefits inverter solutions for crane cranes, gate shafts

The inverter acts as a soft start, when the motor starts, the starting current of the motor is reduced and equal to the rated working current, so it has little impact on surrounding equipment.

- Stable power network quality

- Reduce heat loss on the conductor

- Overcoming voltage drop on the grid.

- Smooth starting and stopping process, reduced noise, increasing motor life

- Increase the life of the welds on the girder and mechanical accessories such as gears, bearings ...

- It is safer for the crane operator when the crane girder is no longer vibrated.

- The inverter will report fault and disconnect 2 motors when one of the two motors has malfunction. Increase the safety of the system.

- Multi-speed speed lifting mechanism: used in the plating industry ...

Economic benefits of inverter solution for crane, gate shaft: Saving electric energy, Reducing maintenance cost

Inverter installation for crane machines is the optimal solution for equipment and energy saving.

Application of Delta VFD CH2000 inverter for crane and gate solution

Improvement of lifting crane system using Delta inverter

Benefits of using Delta CH2000 inverter for crane, gate shaft:

- Avoid voltage drop for the system, improve the quality of the electrical network.

- Reduce vibration, reduce noise. Easy speed synchronization between the lifting mechanism and other mechanical parts.

- The motor is easy to run at multiple speeds, accurately responding to the exact position in load operation requirements.

- Increase shipping productivity. Reduce maintenance and maintenance costs.

Outstanding features of DELTA CH2000 CHARTER for crane crane solution

The outstanding feature of the Delta VFD CH2000 inverter for crane, gate solution

- VFD-CH2000 inverter integrates control modes: V / f, Sensorless Vector, V / f + PG, FOC + PG, PM + PG, FOC Sensorless, TQC Sensorless, PM Sensorless.

- VFD-CH2000 Delta inverter with very high starting torque is suitable for load lifting: over 200% at 0.5Hz under normal conditions and reaching 200% at 0Hz in FOC + PG mode.

- Overload capacity is up to 150% in 60s and 200% for 3s Supports all current advanced control methods such as: Speed, Position, Torque with high precision.

- 4-quadrant control capability, VFD-CH2000 Inverter can run in motor and generator mode, helping to protect the equipment against the possibility of damage in short-term repetitive load applications.

- VFD-CH2000 Delta inverter is integrated with PLC up to 10k Steps for flexible control.

- Heat resistant up to 70oC, integrated EMI filter. The top control boards are coated with powder coating.

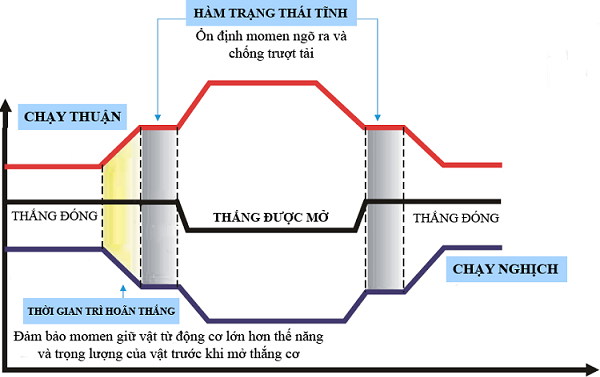

Operation diagram of crane, gate shaft

For details of solution description, please go to Download / Select device "Inverter" / Select document "Application / Appication"

Photos of actual installation project for customers:

Install the inverter for the shaft port

Image of inverter solutions for cranes, gate cranes

Install inverters for elevators, people

Install inverters for elevators, people